Microsaic Systems – signs OEM commercial agreement

Microsaic Systems Signs Commercial Agreement with Leading Global Scientific Company to Create New Analytical Instruments based on ‘Triple Quad’ Technology

25 September 2014: Microsaic Systems plc (AIM: MSYS), the high technology company developing next generation mass spectrometry instruments, is pleased to announce the signing of its first OEM agreement for the development of a chip-based mass spectrometer based on its triple quadrupole (‘triple quad’) technology. The agreement is with a leading global scientific company for use in applied markets.

Colin Jump, Chief Executive of Microsaic Systems, commented:

“We are delighted to begin this major new OEM relationship following successful discussions about the application of our chip-based technologies. In general, our innovative technologies and products have the potential to make chemical analysis using mass spectrometry more accessible to lab scientists. Our triple quad technology extends this opportunity further to encompass the analysis of complex samples, and we look forward to a productive relationship with our new partner going forward.”

Surrey NanoSystems – BBC – Vantablack

How black can black be? See the BBC video here

Microsaic Systems: partnership with Plexus

Microsaic Systems plc, the developer of chip-based scientific instruments, has entered into an agreement with Plexus.

Under the agreement Plexus will provide manufacturing solutions so that Microsaic’s ability to scale up output rapidly is significantly improved.

Colin Jump, chief executive of Microsaic Systems, added, “Outsourcing the manufacture of the 4000 MiD® has been a key strategic aim and we have made considerable investment over the last year to ensure that we are in a position to hand this over to our chosen partner in preparation for production scale up.

“Plexus represents an excellent strategic fit for Microsaic. Its track record and customer base are world class and through this agreement we gain the ability to optimise and scale our manufacturing to meet the increasing demand for our products now and in the future.”

Surrey Nano: UK engineers create world’s darkest material

None more black: UK engineers create world’s darkest material

A radiation-absorbing material developed for space-based applications is finding new applications closer to home.

Vantablack, a so-called ‘super black’ coating from Surrey Nanosystems, combines exceptionally low mass, thermal stability and an ability to absorb 99.96 per cent of incident radiation. Consequently, the coating is suited to applications including apertures, baffles, cold shields and Micro Electro Mechanical Systems (MEMS)–type optical sensors.

The material also overcomes limitations encountered in the manufacture of super-black carbon nanotube-based materials, where high temperatures precluded direct application to sensitive electronics or materials with relatively low melting points. This, along with poor adhesion, prevented their application to space and airborne instrumentation.

Read the full article here.

Vantablack has the highest thermal conductivity and lowest mass-volume of any material that can be used in high-emissivity applications. It has virtually undetectable levels of outgassing and particle fallout, thus eliminating a key source of contamination in sensitive imaging systems. It withstands launch shock, staging and long-term vibration, and is suitable for coating internal components, such as apertures, baffles, cold shields and Micro Electro Mechanical Systems (MEMS) –type optical sensors.

Read the full article here.

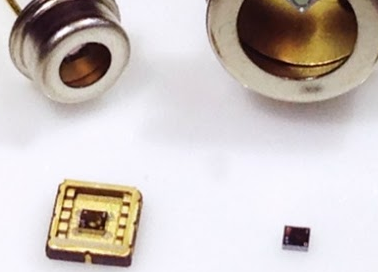

CCMOSS – Parkwalk closes further funding round

We have recently made an investment in Cambridge CMOS Sensors for the UK Tech Fund V and a Parkwalk Syndicate. This follows predecessor funds investing in 2012 and 2013.

Cambridge CMOS Sensors are a leading manufacturer of sensor solutions for monitoring air quality, with a wide range of miniature, ultra-low power gas sensors based on metal-oxide technology and infrared sensor components.

CMOS MEMS platform technology provides a unique silicon platform for CCMOSS’ Metal Oxide (MOX) gas sensors and enables sensor miniaturisation, significantly lower power consumption and ultra-fast response times.

The Micro-hotplates are suspended in a high reliability membrane and act as heater elements for a metal oxide based sensing material. The material resistance will change due to reactions to selected gases and concentrations at temperatures between 200°C to 400°C. Through enabling very fast cycle times, advanced temperature modulation techniques can be used to ensure maximum sensitivity, stability and gas selectivity and minimise measurement times.

Advanced algorithms support the MOX gas sensors family, for maximum selectivity, drift compensation and for self-calibration, enabling easy and timely integration into a wide range of applications.

Microsaic Systems – Signs pre-contract Commercial Agreement

Microsaic Systems Signs Pre-Contract Commercial Agreement with Leading Global Supplier of Scientific Instrumentation in Healthcare Markets

14 April 2014: Microsaic Systems plc (AIM: MSYS), the high technology company developing next generation mass spectrometry instruments, is pleased to announce the signing of a pre-contract commercial agreement to provide its miniature mass spectrometer – the Microsaic 4000 MiD(R) – as an Original Equipment Manufacturer (OEM). The agreement is for the global, exclusive marketing and sale of the 4000 MiD(R) , along with Microsaic’s recently released MiDas interface unit, as a stand-alone instrument for use in protein separation applications. The partner is a major international healthcare equipment company.

The agreement is focused on the use of the 4000 MiD in combination with protein separation, a major application that is used globally and has increasing market demand. It follows a period of R&D collaboration in which Microsaic has successfully adapted and enhanced the 4000 MiD to address this new application.

Microsaic and the partner will now work towards completion and signing of a full commercial contract by the end of the 2014 calendar year. The contract is anticipated to include a commitment to purchase up to 50 units and consumables of the 4000 MiD in the first year, increasing to over 200 units and consumables from the fourth year onwards. The initial period of the contract is expected to be 48 months. The selling price is in line with the Board’s expectations. Shipments under the agreement are anticipated to commence in Q1 2015.

Colin Jump, Chief Executive of Microsaic Systems, commented:

“We are delighted to begin this new OEM relationship with one of the leading global suppliers of healthcare instrumentation. This relationship will introduce a substantial new market segment for Microsaic. We believe that our unique 4000 MiD system has the potential to make mass spectrometry more accessible to lab scientists than ever before, thereby opening up new opportunities across a wide range of applications and formats. This potential is already being realised through our existing partnerships and we are excited about the future prospects for the 4000 MiD and other innovative products being developed.”

Microsaic Systems – appoints FD

Microsaic Systems PLC has appointed Andrew Darby as Finance Director, with effect from April 16.

Bateman will continue as a consultant for a short period in order to support a smooth transition, said the firm.

Darby joins Microsaic on Wednesday April 16 from Active Risk Group PLC, a former AIM-listed company at which he served as Chief Operations Officer and CFO.

Microsaic Systems

Microsaic Systems Showcases Miniaturized Mass Spectrometry at PITTCON 2014: Microsaic Systems, a high technology company developing, marketing and manufacturing next generation mass spectrometry (MS) instruments, is showcasing its latest innovative products offering enhanced productivity and time and cost savings at PITTCON (booth 1051).

………….Read More

Microsaic Systems

Microsaic Systems is pleased to announce the launch of the MiDas™ interface module which allows simple connectivity of its miniaturised mass detector, the 4000 MiD®, for on line and off line analysis. The MiDas compact integrated interface unit offers automated sampling, dilution and injection for direct mass spectrometry (MS) analysis at the lab bench or fume hood, representing a unique integrated solution for delivering main-stream MS analysis to the lab bench.

Colin Jump, CEO Microsaic Systems commented, “The MiDas module adds to the flexibility of our successful 4000 MiD by allowing the simple deployment of mass detection in a large variety of realtime applications. The MiDas interface unit integrates with the 4000 MiD, offering a compact unit which gives the bench chemist the benefits of analytical chemistry where it’s needed.”

Applications range from analysing the compositions of unknown liquids in a beaker to reaction monitoring from a batch, flow reactor to semi-prep LC. MiDas allows sample analysis by direct injection and reaction mixtures from both flow and batch reactors. Masscape software on the 4000 MiD controls the dilution and port in the MiDas for flow and direct injection monitoring. The separate sampling pumps used for batch reaction monitoring are also fully controlled by the software. Automated sample sequences include flushing to ensure no carry-over. Easy-to-use software allows data analysis in real-time. Remote desktop control via LAN is available for remote control of both the MiD and MiDas.

Microsaic Systems is the first and only company to have commercialised mass spectrometry technology on a chip based on MEMS technology. The Microsaic 4000 MiD’s low operating cost and small footprint make the instrument deployable in a wide range of applications where mass spectrometry has not been able to reach. The 4000 MiD fits comfortably into a standard lab fume hood, opening up further opportunities in the field of on-line reaction monitoring. Users are able to increase the use of mass spectrometry in the laboratory, while benefiting from significant cost savings, owing to fewer necessary structural components such as gas generators and air conditioning. There are also sizeable savings with the use of ‘Plug and Play’ components which enable users to maintain the system themselves, resulting in less downtime and greater flexibility within the laboratory.

About Microsaic Systems plc

Microsaic Systems plc is a high technology company developing and marketing next generation mass spectrometry (MS) instruments for the analysis of gaseous, liquid and solid samples. Microsaic has successfully miniaturised mass spectrometry by integrating the key MS components onto patented chip technologies called ionchip®, spraychip® and vac-chip™. Microsaic’s MS products retain the speed and sensitivity of larger, conventional MS systems but are substantially smaller, lighter, consume less energy and have lower running costs. The Microsaic 4000 MiD is the world’s smallest MS system.

Microsaic Systems plc was established in 2001 to develop miniaturised MS instruments based on Micro- Electrical-Mechanical Systems (MEMS) originating at the highly regarded Optical and Semiconductor Devices Group at Imperial College London. Microsaic has subsequently established a large portfolio of 93 patents, of which 58 are granted, and six registered trademarks. For more information, please visitwww.microsaic.com.

Microsaic Systems

Interim results: Revenues up 100%:

Microsaic Systems plc (AIM: MSYS), the developer of chip-based scientific instruments, announces its interim results for the six months ended 30 June 2013 and an update on trading since the period end.

Highlights

· Launch of the Microsaic 4000 MiD® miniature mass spectrometer at Pittcon international trade fair

· Launch of the Isolera™ Dalton by Biotage AB, the first OEM product containing 4000 MiD®

· Signing of OEM agreement for the sale of the 4000 MiD® as a stand-alone instrument

Financial Summary (unaudited)

· Revenues up 100% to £541,529 for first half 2013 (£269,992 for same period in 2012) as product sales grow

· Cash and cash equivalents of £4.8m at 30 June 2013 compared to £1.8m at 31 December 2012

· Loss for period of £1,040,579 (£789,832 in first half 2012). Excluding the distorting effects of accounting for share options, the 2013 first half loss was £1,003,462 compared to £962,299 in 2012.

· Placing of 9,951,443 ordinary shares raising £4.28m before costs

Colin Jump, Chief Executive of Microsaic Systems plc, commented:

“We have continued to make good progress across all areas of our business in the first half of 2013 and have established a solid platform from which to continue to execute our strategy. The launches of the 4000 MiD®and of the Isolera™ Dalton represented important milestones and the market reaction to both has been positive. This growing traction, and the progress we are making in discussions with potential partners and customers, confirm to the Board that there is significant demand for our products across multiple application areas and formats. We are well positioned to meet this demand and create value for our shareholders.”

Microsaic

Microsaic: interim results: Revenues up 100%

Microsaic Systems plc (AIM: MSYS), the developer of chip-based scientific instruments, announces its interim results for the six months ended 30 June 2013 and an update on trading since the period end.

Highlights

· Launch of the Microsaic 4000 MiD® miniature mass spectrometer at Pittcon international trade fair

· Launch of the Isolera™ Dalton by Biotage AB, the first OEM product containing 4000 MiD®

· Signing of OEM agreement for the sale of the 4000 MiD® as a stand-alone instrument

Financial Summary (unaudited)

· Revenues up 100% to £541,529 for first half 2013 (£269,992 for same period in 2012) as product sales grow

· Cash and cash equivalents of £4.8m at 30 June 2013 compared to £1.8m at 31 December 2012

· Loss for period of £1,040,579 (£789,832 in first half 2012). Excluding the distorting effects of accounting for share options, the 2013 first half loss was £1,003,462 compared to £962,299 in 2012.

· Placing of 9,951,443 ordinary shares raising £4.28m before costs

Colin Jump, Chief Executive of Microsaic Systems plc, commented:

“We have continued to make good progress across all areas of our business in the first half of 2013 and have established a solid platform from which to continue to execute our strategy. The launches of the 4000 MiD®and of the Isolera™ Dalton represented important milestones and the market reaction to both has been positive. This growing traction, and the progress we are making in discussions with potential partners and customers, confirm to the Board that there is significant demand for our products across multiple application areas and formats. We are well positioned to meet this demand and create value for our shareholders.”

CCMOSS

Parkwalk closes investment in Cambridge CMOS Sensors for the UK Tech Fund IV & University of Cambridge Enterprise Fund II.

Cambridge CMOS Sensors is the provider of innovative MEMS high temperature microhotplate technology for gas sensing, flow sensing and lab-on-a-chip applications.

The Cambridge CMOS Sensors technology uses standard CMOS processes that enable high volume, low cost and low power sensor-on-chip solutions.

Surrey NanoSystems

‘Super black’ coating to revolutionise aerospace industry?

UK firm Surrey NanoSystems has utilised its know-how in nanotechnology processing to deposit the world’s blackest material on lightweight, temperature-sensitive substrates.

Microsaic

Biotage’s FC-MS System incorporates Microsaic MiD miniature Mass Spectrometer

(AIM: MSYS), welcomes the official launch by Biotage AB (Uppsala, Sweden), a leading global supplier of laboratory equipment, of the Isolera™ Dalton, a fully integrated system for Flash chromatography and mass identification incorporating Microsaic’s novel miniature mass spectrometer – the Microsaic MiD®…..

Microsaic Systems

Parkwalk closes investment in Microsaic Systems plc for the UK Tech Fund IV & ZeroND Fund

Microsaic is the first, and only company to have successfully miniaturised mass spectrometry through the development of its patented chip-based technologies. These technologies are based on Micro-Electrical-Mechanical Systems (MEMS) developed by the Optical and Semiconductor Devices Group at Imperial College.

The Company’s first product, the Microsaic 3500 MiD®, was launched in January 2011 and is the world’s smallest MS system.

Lime Micro

Signs distribution deal with Richardson RFPD

Launch distribution of configurable multi-band, multi-standard transceiver with integrated DACs and ADCs

Richardson RFPD, Inc. recently announced it has completed an agreement to distribute product from Lime Microsystems (“Lime”), an England-based manufacturer that specializes in field programmable RF transceivers (FPRFs) for the next generation of wireless broadband systems. Under the agreement, Richardson RFPD will distribute Lime’s LMS6002D multi-band, multi-standard transceiver worldwide, with the exceptions of Korea and Taiwan…..

CCMOSS

Parkwalk closes Cambridge CMOSS investment for the University of Cambridge Enterprise Fund I and the UK Tech Fund III

Cambridge CMOS Sensors is the provider of innovative MEMS high temperature microhotplate technology for gas sensing, flow sensing and lab-on-a-chip applications.

The Cambridge CMOS Sensors technology uses standard CMOS processes that enable high volume, low cost and low power sensor-on-chip solutions.

Lime Micro

FPGA-based design kit for multiple wireless protocols

Lime Microsystems has developed what it calls a universal wireless communications toolkit which it claims allows developers to create wireless protocols of different complexities. The toolkit comprises Lime’s configurable transceiver board linked to an Altera FPGA design kit via a high speed mezzanine connection (HSMC) interface board. “We believe, this will lead to the development of novel wireless networks at fraction of the cost and time to market,” said Ebrahim Bushehri CEO of Lime. The intention is to support the development of wireless applications ranging from consumer and enterprise broadband equipment through to bespoke white space, military and GNU Radio applications. “Leveraging Lime’s Universal Wireless Communications Toolkit along with our family of tailored 28-nm FPGAs allows designers to rapidly create communications systems optimised for their specific requirements,” said Mike Fitton, senior architect in Altera’s communications business unit.

Lime’s LMS6002D is a fully integrated multi-band, multi-standard single-chip RF transceiver for 3GPP (WCDMA/HSPA and LTE), 3GPP2 (CDMA2000) and WiMAX applications.

It can be digitally configured to operate in 16 user-selectable bandwidths up to 28MHz. In addition to small cell base stations, Lime’s customers are using the IC to create machine to machine (M2M), GNU radio and white space radio applications.

The Lime HSMC interface and transceiver boards are available via Lime Microsystems with FPGA design kits available from Altera.