Microsaic Systems – signs amended agreement with Global Partner

Microsaic Systems plc (AIM: MSYS), the developer of chip-based mass spectrometry instruments, announces that it has signed an amendment to its Research Collaboration Agreement with a long standing global partner. The amended agreement is a precursor to future collaboration in the area of bio-processing.

Interim Chairman, Eric Yeatman commented:

“We are delighted to sign this agreement with one of the foremost players in the global market for scientific instrumentation, which is in line with the Company’s strategy to focus on application areas in biopharma.”

About Microsaic Systems

Microsaic Systems plc is a high technology company developing chip-based, bench-top mass spectrometry (“MS”) instruments that are designed to improve the efficiency of Pharma R&D. MS is an analytical technique of choice for biochemists across many industry sectors.

Microsaic aims to bring routine MS analysis to the pharmaceutical scientist, providing powerful methods of analysis to enable earlier decision making relating to product identification, purity and bioactivity.

The Company is working with established global companies in preparative and purification science with expertise in Pharma and life sciences to co-develop new, integrated and optimised, applicationspecific, solutions to improve productivity in the development of small molecule and novel biologic (peptides, antibodies) medicines.

The Microsaic 4000 MiD®, single quadrupole, is the world’s smallest MS system, retaining the functionality of larger conventional MS systems, is easier to use by non-specialists, consumes less energy and has lower running costs. The Company is also developing new MS systems, based on its patented chip technologies, to address further areas of emerging need in Pharma R&D. Microsaic Systems was established in 2001 by a team including founders from Imperial College London, and was admitted to AIM in 2011 (ticker: MSYS)

Perpetuum article in The Times on remote condition monitoring

Read The Times article on Perpetuum featured in its recent Transportation supplement with interviews with CEO, Steve Turley, and Commercial Director, Justin Southcombe.

Salunda – IGas trial proves the measure of success for hand-held drilling fluid sensor

AN initial field trial of an advanced hand-held analyser has revealed its potential for the rapid and effective testing and measurement of oil and gas drilling fluids.

Independent oil and gas exploration and production company IGas Energy plc develops onshore oil and gas fields and produces more than 2,500 barrels of oil equivalent per day from more than 100 sites across the UK, with other potential sites regularly coming under its control and management.

The company decided to enhance the production on Stockbridge oilfield and to drill three sidetracks from existing wells.

This involved new reservoir development work, which saw the re-entry of existing wells to develop new areas in the field and boost production. The side-tracks were drilled directionally and entered the formations horizontally and completed between 700 and 1,500 metres of new hole from the kick off point in the original wellbores.

An important element of the drilling covered the management and control of the mud fluids, which are designed to fulfil several critical functions including pressure control, lubrication of the wellbore, cuttings removal and hole stability.

The most fluid sensitive rock formations at the Hampshire site were the clays, which were drilled using an oil-based drilling fluid (OBM) requiring measurement at regular intervals for oil, water, solids and chloride content – regular analysis of fluid composition is a pivotal task for mud engineers during any exploration work.

To meet this need, IGas trialled the MudChecker drilling mud analyser from Salunda as a potentially beneficial alternative to the onerous and time consuming retort and titration analysis method. The analyser is the first electronic diagnostic device of its type for the fast and accurate measurement of several critical parameters of Oil-Based drilling fluids.

The Stockbridge trial involved the evaluation of an early MudChecker prototype during several test sessions as an effective way to check the drilling fluids, assessing the hand-held analyser’s capacity to provide rapid and consistent measurement of percentage oil, solid and water volumes when compared to results gained through initial retort analysis.

The trial revealed that the MudChecker, which is also simple and easy to operate, could provide fluid analysis up to six times faster than traditional methods, producing consistently accurate measurement data.

Although its early days, according to Bob Sharp, IGas mud engineer, who oversaw the project as an independent consultant to IGas, the trial has confirmed the potential of MudChecker’s capability in oil and gas exploration and production, as a viable, reliable and cost effective method, with ‘significant potential’ to effectively become a long-term test replacement to retort.

He said: “After some fine tuning, the MudChecker started to produce comparable results to that of the retort method, but far more quickly and consistently. Indeed, I would estimate that usable measurements were provided within 15 minutes when compared to the 90 minutes it took using retort analysis.”

“Moreover, the analyser is much simpler to use, which will be of benefit to mud engineers and operators. The trial revealed that it could significantly cut testing times and improve the efficiency of measuring fluid characteristics, both in the field and in mud plant activities.”

“Using the data MudChecker provides will undoubtedly improve fluids maintenance and checking during drilling activity, enabling changes in content to be made quickly and more accurately. It will also enable companies to perform tests easier and more conveniently; so potentially it should be well received by the global oil and gas industry.”

Incorporating patented, sensitive radio-frequency technology, MudChecker features an integral sensor probe that is used to test a sample to provide an accurate, real time in-field measurement of mud fluid content and temperature.

Consistent and repeatable results are quickly displayed on an integral LCD screen to indicate percentage oil, solid and water volumes. It also records the oil/water ratio (OWR), oil/brine ratio (OBR) and water-phase salinity. Control of these parameters can be critical for mud stability, as well as avoiding wellbore collapse, that might otherwise result in equipment loss or damage, and non-productive time (NPT).

The captured data can be quickly up-loaded via a USB interface to a supporting software programme and can be exported for formal record keeping and reporting. MudChecker comes in a water and solvent resistant rugged enclosure for improved onsite durability and features robust, easy-to-clean stainless steel probes. Salunda propriety software is available to log, export and print-out results quickly and accurately.

The compact analysis unit is supplied as part of a lightweight portable test kit, which includes a mains adapter with interchangeable European and USA adapters, downloadable software and a selection of spare tubes, probes, syringes and proprietary sample mixtures.

Surrey NanoSystems and SBIR agree Vantablack exclusivity

Exclusive rights to the use of ultra-black Vantablack S-VIS surface coating in blackbody calibration sources has been agreed between Surrey NanoSystems and Santa Barbara Infrared (SBIR).

The unparalleled broadband absorption of Vantablack S-VIS makes it ideally suited to enhancing the performance and utility of Santa Barbara Infrared’s (SBIR) precision electro-optical instrumentation, reinforcing its leadership position in military, aerospace IR/FLIR testing and simulation markets. Initially, SBIR is using Surrey NanoSystems’ UK facility to apply the Vantablack coating, while it establishes a local facility to serve the North American defence, aerospace and electro-optical markets.

Commenting on the agreement, SBIR’s President Steve McHugh notes: “The superb broad band absorption of Vantablack coatings, and the highly uniform deposition layer, helps us to create blackbody sources offering extremely high radiometric performance without caveats – greatly enhancing ease of use.”

Surrey NanoSystems’ CEO David Wong adds: “We’re really pleased to have Vantablack recognised by SBIR, who have a reputation built on performance and precision. We’re also delighted to have a partner to simplify procurement and provide local support for Vantablack coatings in North America. We see this as crucial to serving such an important market.”

Surrey NanoSystems’ Vantablack is the world’s blackest surface coating material for the UV to FIR spectrum. It employs an innovative nanomaterial structure that absorbs virtually all incident light. Vantablack was developed for space-borne imaging applications and offers exceptional IR absorption and excellent thermal, mechanical and environmental stability – attributes which uniquely qualify it for the most demanding applications. The material has already achieved space heritage with its recent deployment on an Earth observation satellite.

The S-VIS version of Vantablack traps over 99.8% of near- and mid-infrared wavelengths hitting its surface. It is applied using a simple spraying technique before being post-processed to achieve its exceptional broad band absorption characteristics and near-perfect Lambertian performance. This absorption is maintained over a wide range of wavelengths and viewing angles, far outstripping conventional black paints and other vacuum-deposited coatings. These characteristics are critical for SBIR’s specialised equipment, where compliance with rigourous US defence standards, long-term stability and traceable precision are essential attributes.

The active element of Vantablack S-VIS is a functionalised carbon nanotube matrix. The coating is applied using a proprietary process that includes a number of pre- and post-application steps to achieve its ultra-low reflectance. The process is scalable and suitable for high-volume production on both small and large substrates, and on complex 3D surfaces. Vantablack S-VIS can be applied to a variety of substrates, with the only major constraint being the ability of the substrate to withstand process temperatures of 100-150 degrees Centigrade, making the coating suitable for application onto many popular types of engineering-grade polymers and composite materials.

Since its launch in spring 2016, well over 100 Vantablack S-VIS projects have already been completed, including in space-borne instrumentation and military optical systems.

The agreement with SBIR provides the next platform for the further adoption of the technology.

Microsaic Systems – Parkwalk Opportunities Fund closes follow on investment

We are delighted to have participated in a placing for Microsaic Systems:

12 September 2016

On 26 August 2016, Microsaic Systems plc (AIM: MSYS), the developer of chip-based mass spectrometry instruments, announced a proposed Placing to raise up to £5.4 million (before expenses) through the issue of up to 108,000,000 new ordinary shares of 0.25p each (“New Ordinary Shares”) at an issue price of 5 pence per New Ordinary Share.

The Company is pleased to announce that, at its General Meeting held earlier today, the Resolution put to shareholders to authorise the directors of the Company to allot the New Ordinary Shares in connection with the proposed Placing was duly passed.

Further to this, the Company can now confirm that it will issue, pursuant to the Placing, 108,000,000 New Ordinary Shares at 5 pence per share, raising £5.4 million (before expenses). Application has been made for the 108,000,000 New Ordinary Shares to be admitted to trading on AIM and it is expected that Admission will become effective and trading will commence in the New Ordinary Shares at 8.00 a.m. on 13 September 2016. Following Admission the Company’s issued share capital will comprise 181,365,146 Ordinary Shares. From Admission, the figure of 181,365,146 may be used by shareholders in the Company as the denominator for the calculations by which they will determine if they are required to notify their interest in, or a change to their interest in, the share capital of the Company under the FCA’s Disclosure Guidance and Transparency Rules.

Colin Nicholl, Chairman of Microsaic, said:

”We are grateful to our existing shareholders as well as new investors for supporting this issue. The funds raised will provide the Company with the resources to develop our existing partnerships, secure additional relationships, and to increase the spread of applications that are addressed. This in turn will allow the business to grow in a profitable way.”

Salunda – Parkwalk follow-on Investment

We have recently closed an investment in Salunda for the Parkwalk Opportunities Fund.

Salunda develops robust, contactless sensors for use in very harsh environments. The company’s sensor technology detects position and speed, and measures the composition of fluids.

Salunda has developed patented, contactless sensor technology for monitoring machinery in very harsh environments. Sensors scan components such as pistons, rotors and seals for wear and failure. A profile of the component surface can be recorded with sensitivities of as little as tens of microns. Sensors can warn of imminent failure by detecting cracks, eccentric motion, ‘orbiting’, axial shift or vibration.

The oil industry requires accurate, repeatable measurement of the separation of water, oil and gas. Salunda is developing reliable, inline sensors that measure the water content of crude oil, contamination and actual fluid level in the presence of bubbles and froth. OEM components based on patented technologies are available for open-bore water cut and multiphase flow application.

Parkwalk portfolio company CCMOSS – acquired by ams AG to become world leader in gas and infrared sensing

ams AG (SIX: AMS), a leading worldwide manufacturer of high performance sensor and analog solutions, has acquired 100% of the shares in Cambridge CMOS Sensors Ltd (CCS), the technology leader in micro hotplate structures for gas sensing and infrared applications, in an all-cash transaction.

Founded in 2008 as a spin-off from Cambridge University, with the start of technology development dating back to 1994 in collaboration with the University of Warwick, CCS has built an outstanding expertise in micro hotplate design and manufacturing for gas and infrared sensing over more than 20 years. Parkwalk and Cambridge Enterprise, the commercialisation arm of the University of Cambridge, have supported CCS throughout its development.

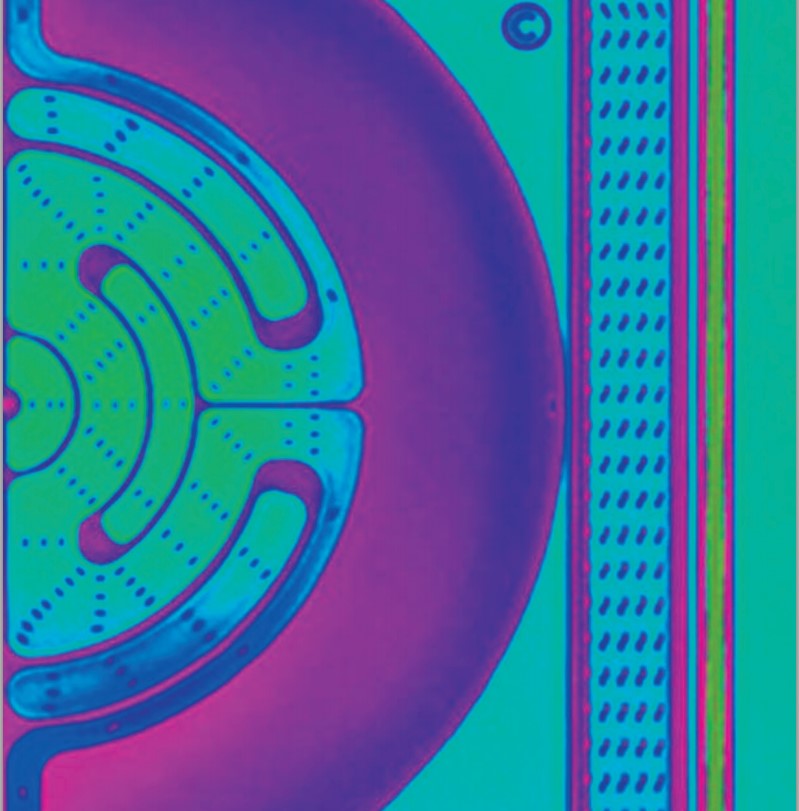

CCS’ micro hotplates are MEMS structures that are used in gas sensors for volume applications in the automotive, industrial, medical, and consumer markets. The company’s deep expertise in this area is highly synergetic with ams’ technology leadership in MOX gas sensing materials to detect gases like CO, NOx, and VOCs. CCS manufactures these MEMS structures on CMOS wafers allowing the creation of complete monolithically integrated CMOS sensor ICs. This makes CCS’ solutions highly cost-efficient, besides offering other significant advantages over competing technologies like low power consumption, small footprint and the ability to integrate additional sensor modalities like relative humidity, temperature, and pressure.

“The addition of CCS makes ams the clear leader in gas and infrared sensor technology worldwide, and completes ams’ portfolio of products and technologies for the environmental sensor market.”

Alexander Everke

In addition, CCS commands an industry-leading portfolio of IR technology comprising high performance IR radiation sources and detectors for sensor applications. Highly complementary to ams’ spectral sensing strategy for next generation optical sensor technologies, CCS’ IR sensing is based on the same monolithic CMOS structures as for gas sensing, enabling miniaturised implementations and efficient integration with other on-chip functions. Applications include CO2 gas sensing and human presence detection and will extend into spectroscopic identification of organic materials.

CCS’ corporate headquarters are located in Cambridge, UK, and the company has 33 employees. The Cambridge region has become a centre of innovation for sensor technologies globally so ams values the ability to gain direct access to this attractive ecosystem going forward.

The parties to the transaction have agreed to keep the consideration confidential. ams plans to fully integrate CCS’ activities into its existing environmental sensor business, which has development locations in Eindhoven, the Netherlands, and Reutlingen, Germany.

Perpetuum – Eversholt adopts Perpetuum system to monitor Southeastern Class 465s

Perpetuum has been awarded the contract to supply a sensor system for Eversholt Rail to use in monitoring the condition of eight Southeastern trains.

The Perpetuum system will be used on eight London Southeastern Class 465 trains while they are in service to extend wheelset overhauls and improve reliability.

Mark Johnson, engineering director of Southeastern, said: “London Southeastern has been committed to maximising the performance of its fleets as it endeavours to deliver some of the most challenging timetables in the country.

“Using live information on the bogie’s true condition to inform our maintenance regime has been instrumental to this, along with building a systems approach to asset management by integrating track condition into the wheelset management decision making.”

Perpetuum’s self-powered system, which has previously been used by Eversholt on Bombardier Class 375s and 376s and Alstom Class 466s, produces vibration and temperature data – enabling clients to view the real-time health and predict the failure of rotating components on trains, such as wheel bearings, motors and gearboxes.

Steve Turley, CEO of Perpetuum, said: “We are extremely pleased to continue our collaboration with Eversholt Rail and Southeastern, helping to change the expectations of what can be achieved with existing rolling stock by using methodologies proven in other sectors.”

Andy Course, chief operating officer of Eversholt Rail, added that wheelset and bogie condition monitoring is part of an ever larger Eversholt Rail policy of moving its maintenance methodology towards a “data-driven and real-time operation that will increase availability and reduce cost for our valued clients, like London Southeastern”.

Perpetuum has also been awarded a contract to install wireless sensor systems to monitor when maintenance is needed on Govia Thameslink trains.

Microsaic Systems – appointment of Broker

Microsaic Systems plc (AIM: MSYS), the developer of chip-based mass spectrometry instruments, is pleased to announce that Nplus 1 Singer Advisory LLP (“N+1 Singer”) has been appointed as Nominated Adviser and Broker to the Company with immediate effect.

Microsaic Systems plc is a high technology company developing and marketing next generation mass spectrometry (MS) instruments for the analysis of liquid samples. Microsaic has successfully miniaturised mass spectrometry into a desktop instrument by integrating the key MS components onto patented chip technologies (called ionchip®, spraychip® and vac-chip™). Microsaic’s MS products retain the functionality of larger, conventional MS systems but are substantially smaller, lighter, consume less energy and have lower running costs. The Microsaic 4000 MiD® is the world’s smallest MS system. MS is a ‘gold-standard’ analytical technique used across many industry sectors, including pharmaceutical, diagnostics and healthcare, government, energy, utilities, environmental, food and drink, security and defence, and industrial chemicals. Microsaic Systems was established in 2001 by a team including founders from Imperial College London, and was admitted to AIM in April 2011 under the symbol MSYS.

Perpetuum – Parkwalk closes follow on investment

We have recently closed a follow-on investment in Perpetuum for the Opportunities EIS Fund, alongside existing investors IP Group and ETF.

Perpetuum engineered, produced and commercialised the world’s first practical electromagnetic vibration harvesting micro-generator delivering the power required to transmit large amounts of autonomous wireless sensor data reliably from remotely monitored assets.

Perpetuum’s technology provides self-powered wireless conditioning monitoring solutions for rail applications and perpetual power for wireless industrial automation applications.

Perpetuum’s sensors are simple to install with no batteries and no wires, condition data is sent to the cloud where Perpetuum’s algorithms read the data and provide information management systems to customers online.

The company’s website can be viewed here.

CCMOSS – Parkwalk closes further funding round

We have recently made an investment in Cambridge CMOS Sensors for the Parkwalk Opportunities EIS Fund and the University of Cambridge Enterprise Fund III.. This follows predecessor funds investing in 2012 and 2013.

Cambridge CMOS Sensors is a leading manufacturer of sensor solutions for monitoring air quality, with a wide range of miniature, ultra-low power gas sensors based on metal-oxide technology and infrared sensor components.

Cambridge CMOS Sensors is a spin-out from University of Cambridge and is exploiting innovative patented technology jointly developed in collaboration with the University of Warwick. The company aims to be a technology provider of CMOS MEMS structures such as basic and smart micro-hotplates, semiconductor sensors (gas sensors, mechanical sensors, temperature sensors & flow sensors) and nano-MEMS and nanosensors and a leading manufacturer of mid-infrared emitter.

CMOS MEMS platform technology provides a unique silicon platform for CCMOSS’ Metal Oxide (MOX) gas sensors and enables sensor miniaturisation, significantly lower power consumption and ultra-fast response times.

The Micro-hotplates are suspended in a high reliability membrane and act as heater elements for a metal oxide based sensing material. The material resistance will change due to reactions to selected gases and concentrations at temperatures between 200°C to 400°C. Through enabling very fast cycle times, advanced temperature modulation techniques can be used to ensure maximum sensitivity, stability and gas selectivity and minimise measurement times.

Advanced algorithms support the MOX gas sensors family, for maximum selectivity, drift compensation and for self-calibration, enabling easy and timely integration into a wide range of applications.

Perpetuum – Parkwalk closes follow on investment

We have recently closed a follow-on investment in Perpetuum for the Parkwalk UK Tech Fund VI and the Opportunities EIS Fund, alongside existing investors IP Group and ETF.

Perpetuum engineered, produced and commercialised the world’s first practical electromagnetic vibration harvesting micro-generator delivering the power required to transmit large amounts of autonomous wireless sensor data reliably from remotely monitored assets.

Perpetuum’s technology provides self-powered wireless conditioning monitoring solutions for rail applications and perpetual power for wireless industrial automation applications.

Perpetuum’s sensors are simple to install with no batteries and no wires, condition data is sent to the cloud where Perpetuum’s algorithms read the data and provide information management systems to customers online.

The company’s website can be viewed here.

Microsaic Systems – agreement with GE Healthcare

Microsaic Systems plc, the high technology company developing next generation mass spectrometry (MS) instruments, is pleased to announce it has signed an OEM (original equipment manufacturer) supply agreement with GE Healthcare, for the sale of its 4000 MiD® unit in combination with GE Healthcare’s instruments. The agreement, which is the culmination of work done under a previously announced ‘pre-commercial agreement’ (14 April 2014), is centred on the development and commercialisation of an innovative new analytical instrument for use in research and healthcare applications. The two companies are working towards the commercial launch of the integrated product, expected in 2016. Forecast contract volumes are in line with the announcement made on 14 April 2014. The first year of the contract will be extended to the period between the commencement of the contract and 31 December 2016.

Colin Jump, Chief Executive of Microsaic Systems, commenting on the agreement, said:

“We are delighted to sign this agreement with GE Healthcare, one of the foremost players in the global market for scientific instrumentation. Over the last year, teams from both companies have established a close and productive relationship and together we are focused on completing the development of this highly innovative instrument and launching it as soon as possible.”

Surrey NanoSystems – Follow on investment

Parkwalk are pleased to announce a follow on investment into Surrey NanoSystems by the Parkwalk Opportunities EIS Fund and a Parkwalk Syndicate.

Spun-out of the University of Surrey in 2006, Surrey NanoSystems has raised around £8m in equity funding to date as well as substantial non-dilutive grant funding. Parkwalk made its first investment in 2012.

Surrey NanoSystems produces nanostructured materials such as carbon nanotubes (CNTs) and graphene using its proprietary low-temperature synthesis technology. This low-temperature synthesis capability, realised using specialised, custom-built equipment, enables these “wonder materials” to be used in real-world applications, where conventional synthesis temperatures would otherwise be too high.

Using this technology, the Company developed Vantablack®, launched at the Farnborough International Air Show in the summer of 2014. Vantablack® is revolutionary in its ability to be applied to light-weight, temperature-sensitive structures such as aluminium whilst absorbing 99.96% of incident radiation, believed to be the highest-ever recorded.

The company’s website can be viewed here.

Salunda – University of Oxford Isis Fund I Investment

We have recently closed an investment in Salunda for the University of Oxford Isis Fund I.

Salunda develops robust, contactless sensors for use in very harsh environments. The company’s sensor technology detects position and speed, and measures the composition of fluids.

Salunda has developed patented, contactless sensor technology for monitoring machinery in very harsh environments. Sensors scan components such as pistons, rotors and seals for wear and failure. A profile of the component surface can be recorded with sensitivities of as little as tens of microns. Sensors can warn of imminent failure by detecting cracks, eccentric motion, ‘orbiting’, axial shift or vibration.

The oil industry requires accurate, repeatable measurement of the separation of water, oil and gas. Salunda is developing reliable, inline sensors that measure the water content of crude oil, contamination and actual fluid level in the presence of bubbles and froth. OEM components based on patented technologies are available for open-bore water cut and multiphase flow application.

Surrey NanoSystems – NYT: Into the Void

New York Times article: Gazing Into the Void – What You Can Do With Vantablack, the Darkest Material Ever Made

Read the article here.

Microsaic Systems – Parkwalk closes follow on investment

We are delighted to have participated in a conditional placing for Microsaic Systems:

7 October 2014: Microsaic Systems plc (AIM: MSYS), the high technology company developing next generation mass spectrometry instruments, is pleased to announce a conditional placing (“Placing”) of 10,500,000 new ordinary shares of 0.25p each (“Placing Shares”) at a price of 42 pence per share to raise £4.4 million (before expenses).

Highlights:

· £4.4 million to be raised by way of a conditional Placing to certain existing and new institutional and other investors at a price of 42 pence per Placing Share (representing a discount of approximately 6.7 per cent. to the closing mid-market price of 45 pence on 6 October 2014)

· Aggregate participation in the Placing by Microsaic directors of approximately £125,000

· Net proceeds of the Placing will be deployed to further the growth plans of the Company

· Admission of the Placing Shares expected on 10 October 2014

The net proceeds of the Placing will provide the Company with the additional working capital and capital resources to execute its organic revenue growth plans, which include: (i) generating volume sales of its miniaturised MS (mass spectrometry) system by establishing the Company as an OEM partner (Original Equipment Manufacturer) to market leaders in scientific instruments in a number of parallel application areas and developing its own sales channels to customers in niche, growth application areas; (ii) accelerating the commercialisation of its products and technologies, negotiating complex customer contracts and further outsourcing of manufacturing; and (iii) to provide a strong financial position from which to support commercial negotiations.

The Placing will also enable the Company to continue investing in the development and production of its instruments and technologies. Development plans include variants of the 4000 MiD® for specific applications, enhancements to the ‘Plug & Play’ functionality of the 4000 MiD®, as well as further development and productisation of the Company’s triple quadrupole MS system in collaboration with partners.

The Placing is conditional, as described more fully below.

Colin Jump, Chief Executive of Microsaic, commented:

“Microsaic continues to make good progress in putting in place the key elements of its business that are designed to reinforce its leadership in miniaturised mass spectrometry and drive shareholder value. These include two further OEM agreements with industry leaders over the past year for the global development and commercialisation of scientific instruments that incorporate the Company’s mass spectrometry technologies; outsourcing manufacturing to meet increasing commercial demand; and continuing innovation to make our offering more attractive across the multiple application areas targeted. These new funds will continue to fuel the growth and development of Microsaic’s business and we thank existing and new shareholders for their support of the Company.”

Read the full RNS here.

Perpetuum – Parkwalk UK Tech V & Opportunities Fund investment

We have recently closed an investment in Perpetuum for the Parkwalk UK Tech Fund V, Opportunities Fund and a Parkwalk Syndicate.

Perpetuum engineered, produced and commercialized the world’s first practical electromagnetic vibration harvesting micro-generator delivering the power required to transmit large amounts of autonomous wireless sensor data reliably from remotely monitored assets.

Perpetuum’s technology provides self-powered wireless conditioning monitoring solutions for rail applications and perpetual power for wireless industrial automation applications.

Perpetuum’s sensors are simple to install with no batteries and no wires, condition data is sent to the cloud where Perpetuum’s algorithms read the data and provide information management systems to customers online.

The company’s website can be viewed here.

Microsaic Systems – agreement with Gilson Inc

Microsaic Systems Signs Commercial Agreement with Gilson Inc. to Create New Analytical Instruments for the Pharmaceutical and Life Science Industries

29 September 2014: Microsaic Systems plc (AIM: MSYS), the high technology company developing next generation mass spectrometry instruments, is pleased to announce the signing of a commercial agreement with Gilson Inc., a leading international scientific instrumentation company, to create new analytical instruments for the pharmaceutical and life science industries.

Under the terms of the agreement, Microsaic with provide its miniature mass spectrometer – the Microsaic 4000 MiD® – as an Original Equipment Manufacturer (OEM). Gilson will combine the 4000 MiD® with its high performance liquid chromatography instruments to create a new product for the rapid separation and characterisation of liquid samples in pharmaceutical research and development.

Microsaic anticipates commencing shipments of its 4000 MiD® to Gilson in Q1 2015 with volumes rising to approximately 50 units per year in due course. The selling price per unit is in line with the Board’s expectations. Further details are not disclosed.

Colin Jump, Chief Executive of Microsaic Systems, commented:

“We are delighted to begin this new OEM relationship with Gilson, an industry leader in manufacturing manual and automated liquid sample management products. This agreement represents the achievement of another milestone for the company towards its goal of becoming a leader in the miniaturised instrumentation market. We have high quality global partners for our products addressing an increasing proportion of our target market and continue productive discussions with other potential partners, which we anticipate will progress to agreements in the future.”

Nicolas Paris, Chief Executive of Gilson, Inc. commented:

“The combination of Gilson’s systems flexibility and the Microsaic 4000 MiD® detector brings the power of MS purification to non mass-spec experts in a very innovative, affordable and easy-to-use package. We, at Gilson, are convinced this agreement will help our customers to simplify their sample prep workflows with a better and more routine mass spec solution.”

ARM Holdings – £24.3bn acquisition of the University of Cambridge spin-out

Japan’s Softbank on Monday offered £24.3bn ($32bn) in cash to acquire 100% of ARM Holdings, the UK’s smartphone chip designer that is one of the leaders in the infrastructure of the internet of things.

In 2015, Forbes ranked ARM as the most innovative company in Europe, and the fifth most innovative in the world.

The deal values ARM at 24.4x 2015 revenues or 56.8x 2015 EBITDA.

We believe this is further proof of the value of UK University spin-outs, and their global appeal – ARM have world-wide sales and are unaffected by Brexit as Philip Hammond, the UK’s Chancellor of the Exchequer, said: “Just three weeks after the referendum decision, it shows that Britain has lost none of its allure to international investors.”

“as ARM’s founders will testify, this is the greatest place in the world to start and grow a technology business,” he added.

Softbank’s investment would be the largest ever from Asia into the UK. The deal would “guarantee to double the number of jobs in ARM in the UK over the next five years and turn this great British company into a global phenomenon”.

Over 70bn ARM-designed chips have been shipped to date, with 95% of the world’s smartphones containing at least one ARM-based component, and Canalys estimate 80% of wearable devices sold in 2014 contained at least one ARM-based chip.

Last month Cambridge CMOS Sensors, another spin-out creating next generation internet of things sensors was acquired by ams AG – more detail can be seen here.

Posted on July 18, 2016

Electronics, Fund Managers Comments, Semiconductors

Cambridge, Electronics, Semiconductors