Xeros

Parkwalk closes further investment in Xeros on successful £10m raise

Xeros’ mission is to convert the $100bn global laundry industry to Xeros polymer bead cleaning.

Up to 80% less water, 50% less energy and 50% less detergent is used in the Xeros system versus conventional washing.

If all UK households were fitted with machines powered by Xeros technology, the potential annual savings to UK consumers would be £2bn and would reduce CO2 emissions by 4.2m tonnes – the equivalent of taking 1.4m cars off UK roads.

The technology was launched commercially in late 2012 with successful affirmation sites in London & the US.

Xeros

Triumphs at Rushlight Awards 2013

Xeros has won two of the UK’s most coveted green innovation awards at Rushlight Awards 2013, held in the presence of Rt. Hon Greg Barker MP, Minister of State for Energy & Climate Change, and representatives from across the cleantech investment and green innovation spectrum.

Xeros was named winner of the Rushlight Sustainable Manufacturing & Services Award and the winner of the Rushlight Environmental Management Award. The latter award represents the best technology, product or service chosen by judges from the winners of five Rushlight awards categories. These included the Clean Environment award, Responsible Product / Service award, Sustainable Agriculture, Forestry & Biodiversity award, Environmental Analysis & Metrology award and Sustainable Manufacturing & Services award.

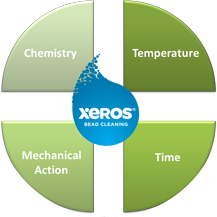

Xeros cleans clothes with very little water and patented Xeros polymer beads. The cleaning system comprises a special washing machine designed to release the beads into the drum for cleaning, and removing the beads from the clothes once the cleaning is complete. Up to 80% less water, 50% less energy and 50% less detergent is used in the Xeros system versus conventional washing, yet Xeros delivers superior cleaning results.

The $100 billion global laundry industry is the initial market for the Xeros polymer bead cleaning system. The technology launched into the commercial laundry market in late 2012 with initial sales into UK and US laundries.

Bill Westwater, Chief Executive Officer of Xeros, said: “We are delighted to have been recognised for the overall environmental and performance benefits of the Xeros cleaning system. We have a big but simple idea: to convert the traditional world of aqueous washing to Xeros polymer bead cleaning. These awards represent another milestone in our journey towards making that idea a reality.”

Clive Hall, Founder/ CEO of Eventure Media, which runs the Rushlight Awards, said: “The savings on water, detergent and power are impressive as is the potential to extend the life of garments.”

OxfordPV

Parkwalk closes OxfordPV follow-on investment

OxfordPV has developed a new solar cell technology that is manufactured from inexpensive, abundant, non-toxic and non-corrosive organic materials and can be scaled to any volume.

The technology replaces the liquid electrolyte with a solid organic semiconductor, enabling entire solar modules to be screen printed onto glass or other surfaces.

YASA

Parkwalk closes Oxford YASA Motors investment.

YASA Motors is a dynamic and innovative electric motor company bringing a new generation of high power and high torque density electric motors to market.

The Company has developed class leading axial flux traction motors for use in both Automotive (EV’s & HEV’s) and also Industrial applications

Xeros

Second affirmation site in the US

RESTON, Va.–(BUSINESS WIRE)–Xeros Ltd, the UK-based innovator of a “virtually waterless” laundry cleaning system, announced today that the Hyatt Regency Reston, Virginia will become an affirmation participant and begin using Xeros’ proprietary cleaning solution for its guestrooms and restaurant. The revolutionary, eco-friendly Xeros washing machine was installed at the property on Tuesday, December 4th to expertly launder Hyatt’s guest room and dining room linens and bath towels using less water, less chemicals and less energy than traditional methods. This marks the second affirmation site for Xeros in the United States. The company first entered the US market in September 2012 with its first washing machine placed at Sterling Linens in Manchester, New Hampshire…..

Clean Air Power

Contract Win

Clean Air Power (AIM:CAP), the developer of Dual-Fuel™ combustion technology that enables heavy-duty diesel engines to operate on a combination of diesel and natural gas, is delighted to announce that it has received a significant Genesis Edge systems order from a European logistics operator.

Clean Air Power, which launched a new Renault Magnum compatible Genesis Edge Dual-Fuel™retrofit system earlier this year, has received an order for a further 30 systems. This is in addition to an order previously received for 50 systems from the same Spanish customer announced in April.

These new systems will be delivered to the customer during 2012 and is further confirmation that this new system is being well received and delivering the expected financial and environmental benefits.

Commenting on the announcement, John Pettitt, CEO of Clean Air Power said:

“This is a significant order for Clean Air Power and follows a previous order from the same customer earlier this year.

Clean Air Power’s progress, together with the increasing recognition of natural gas as a road fuel among major manufacturers and global fuel providers, is very encouraging. Our range of product offerings continues to develop and will give us the opportunity of entering new markets, both for our retrofit and our OEM systems.”

Clean Air Power

Parkwalk closes Clean Air Power investment for the UK Tech Fund III

Clean Air Power has pioneered the move towards using natural gas to power vehicles by developing Dual-Fuel™ technologies that guarantee diesel engine performance, with significant cost savings and low carbon emissions.

Minimal changes are required to the existing diesel engine and by burning up to 90% natural gas, customers benefit from a combination of low emissions and high efficiency.

ACAL Energy

Vince Cable MP visit to ACAL Energy

Rt Hon Vince Cable MP, Secretary of State for Business, Innovation and Skills met with Liverpool City Region LEP representatives last week. (Thursday 18th October 2012)….

OxfordPV

Oxford researchers have developed a photovoltaic (PV) technology that has the potential to deliver low cost, efficient solar cells that can be readily incorporated into glass building facades. Results just released in the journal Science promise to provide the lowest cost-performance photovoltaic solution on the market. The technology makes use of a simple manufacturing process with inexpensive and abundant raw materials. Prototypes of these new Meso-Superstructured Solar Cells (MSSC) demonstrated in the journal have already achieved an impressive 10.9% efficiency…..

Xeros

Deputy Prime Minister Clegg visits Xeros

Xeros, the company responsible for the development of the “virtually waterless” laundry system, has set its sights on sales in both the UK and North American commercial laundry industries.

Xeros’ technology uses a fraction of the water, energy and detergent required for conventional cleaning methods, and provides significant cost-saving and environmental benefits. Through the use of polymer bead technology, this revolutionary cleaning process has been proven more effective than traditional methods.

By combining the beads’ molecular structure with a proprietary detergent solution, the result is a superior cleaning medium that beats even water. The dirt from soiled items is attracted and absorbed by the beads, producing cleaner results than aqueous washing methods.

In the US, the Xeros system has been installed at Manchester, New Hampshire’s Sterling Linen Services, a high-quality linen processing and rental service for area hotels, hospitals and restaurants. Meanwhile in the UK the company are celebrating the sale of its first machine to high street laundry chain, Johnsons.

Xeros plan to officially roll-out their commercial solution at the 2013 Clean Show for the commercial laundry marketplace, with a household sized machine in development for launch in 2014. The first Xeros machines – capable of washing up to 25kg of clothes at a time – are aimed at the commercial cleaning market, which includes hotels and institutions like prisons and hospitals, as well as high street cleaners.

Deputy Prime Minister, Nick Clegg recently toured Xeros’ facility at the Advanced Manufacturing Park (AMP) in Rotherham. During the visit he commented; “It takes your breath away. It is such a simple idea, but it is so revolutionary,” said Mr Clegg. “It could save billions and billions of litres of water over time. The implications are profound in terms of water and energy use.

“This is a great example of what we want to see happening in the British economy. It was academics that first came up with the idea and it has been translated, partly thanks to support from the government and private investors, into something that hopefully make its way into the shops fairly soon.”

Xeros was named a top invention by TIME magazine, winner of ‘Best Technological Breakthrough’ in The Climate Week Awards 2011; listed in WWF’s survey of global ‘Green Game Changers’ and selected as one of 19 best fast-growing ‘Clean and Cool’ companies to go on a government-sponsored mission to Silicon Valley in February, 2010.

OxfordPV

Dr Henry Snaith wins Paterson Medal

Dr Henry J Snaith, Clarendon Laboratory, University of Oxford.

For his important contributions to the field of excitonic solar cells.

Henry Snaith is a leading figure in excitonic solar cell research and in organic and hybrid optoelectronics. His activities range from nanomaterials synthesis through to device fabrication and optimisation, optical spectroscopy and theory. He has studied a number of device systems including LEDs, polymer lasers, polymer solar cells and transistors, but focuses his efforts on solid-state dye sensitised solar cells (DSSC). DSSC technology has a real chance of becoming a major future power source, with very low basic materials and processing cost. Snaith has made significant contributions to the study of charge generation and transport mechanisms in polymer blend, hybrid and dye-sensitised solar cells: he has introduced new device concepts and new optoelectronic methods to analyse these nanocomposite materials….

Arvia

Takes decontamination solution to Japan

North West technology company Arvia has been asked to take its water treatment technology to Japan as part of the cleanup of nuclear waste. Asia market access specialist Intralink will support Arvia with a bilingual team, and assistance in establishing a local office. Arvia’s multi-award winning method of water treatment removes and destroys toxic non-biodegradeable contaminants, with one of the major applications being the disposal of organic radioactive waste. Martin Keighley, CEO of Avria, said: “Japan has a big problem with low and intermediate level radioactive oil which is notoriously difficult to dispose of. “Current methods include incineration and encapsulation which can both have a serious impact on the environment. “Neither of these solutions is ideal, and our technology is unique in that it enables the clean, safe and cost-effective disposal of radioactive waste – something of a holy grail for the nuclear industry.” Following successful trails at the Magnox nuclear decommissioning site in Trawsfynydd in North Wales, Arvia recognised the need for the solution in Japan. Low and intermediate level organic radioactive waste is becoming increasingly problematic at a number of sites in the country. Huw Thomas, MD of Intralink Japan, said: “Arvia’s unique treatment technology is ideally positioned to help solve some of the problems in the nuclear industry here. “Intralink’s Surrogate Sales Program will enable Arvia to enter this market and engage quickly with the leading Japanese players in nuclear and other waste treatment applications.”

Xeros

Debuts in ‘Home of the Future’

Xeros debuted its revolutionary, environmentally friendly cleaning process on Channel 4 in a new series that shows how an ordinary Sheffield family can use cutting edge technologies and gadgets to tackle challenges such as energy and water use, as they seek to adapt to low carbon living. The series follows the Perera family at ‘work, rest and play’ and shows what they might eat, how they might travel, stay healthy and power their homes in the future. It poses various challenges to the family and offers a glimpse into what solutions are available now and in the future. Xeros featured in a programme titled ‘Work,’ which aired on 19 February 2012 (19.30, Channel 4).

Bill Westwater, Chief Executive of Xeros welcomed Channel 4 to the company’s R&D facility at the Advanced Manufacturing Park in Sheffield in August last year, to show how the technology transforms the way clothes are cleaned by a process that uses polymer beads to ‘attract’ stains. The gentle flow of small polymer beads acts just like hand washing, tumbling with the washload and transporting stains off garments to be locked into the bead molecular structure. This exceptional environmental system uses only a fraction of the water, energy and detergent that is required for conventional cleaning.

Bill Westwater, Chief Executive Officer of Xeros, said: “We were delighted that the programme makers chose to feature Xeros technology in action. The programme aims to tackle serious challenges to British households facing up to rising energy and water bills and how they can take affordable steps to live in more sustainable ways.”

Arvia

Parkwalk closes Arvia investment for the UK Tech Fund II

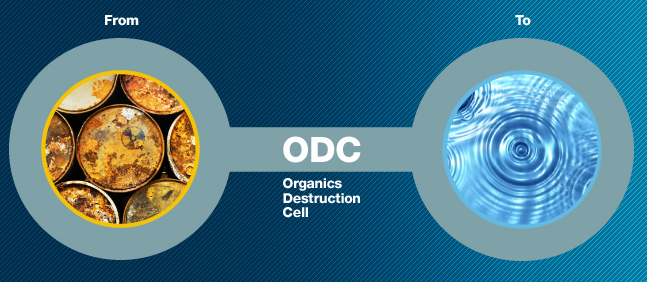

Arvia represents a dramatic change from the traditional methods for treating organic liquid waste.

This ‘game changing’ technology removes and destroys organic contaminants and oils using a method that is free of process chemicals, is energy efficient, and produces little solid or liquid waste for disposal.

ACAL Energy

Shows New Fuel Cell Stack Design

Cheshire, UK – 14th March 2012 – ACAL Energy attracted a lot of interest at the FC EXPO show recently, when it unveiled a new, compact, low cost fuel cell stack design with a rated power of 12 kW and a power density of over 1 kW per litre. The new design is six times smaller than the previous generation, and is expected to be of interest in both automotive and stationery power generation applications.

The design was shown as the company exhibited its platinum-free fuel cell technology at FC EXPO in Japan where a total of almost 100,000 visitors had the opportunity to see it. The annual FC EXPO show is the world’s largest exhibition and conference specialised in Hydrogen & Fuel Cell technology.

The ACAL Energy stand was buzzing with interest from both suppliers and integrators from all around the world, who were keen to hear of the progress being made with its FlowCath® technology. FlowCath® is becoming well known as a means of replacing the precious metal catalyst found in conventional fuel cells with a proprietary low cost liquid catalyst. This inherently eliminates many of the causes of lost performance in both continuous operation and in auto cycling.

“Asian markets, and Japan in particular, are important to us as we develop our commercialisation strategy”, said Bob Longman who was present at the show. “Our compact 12kW design clearly addresses the need for higher power fuel cell engines with reliability built in to the design.”

The ACAL Energy stand at FC EXPO was jointly organised with the Japanese company Sumitomo, which is an investor in the company. FlowCath® technology has the potential significantly to reduce the future cost for vehicle OEMs, and system integrators planning to deploy fuel cells in mass markets. FC EXPO 2012 was part of World Smart Energy Week 2012 which occupied the whole of the Tokyo Big Sight exhibition venue and pulled together a wide variety of cutting-edge technologies in ‘smart energy’ sectors.

ACAL Energy

FT: UK seeks to keep lead in fuel cells

Britain is staking its claim to lead the race to find a carbon-free car engine by bringing two innovative hydrogen power companies together.

Acal Energy, which has developed a cheap fuel cell, and ITM Power, an Aim-listed maker of hydrogen for fuel, have been given £500,000 – with the promise of up to £5m more – by the Carbon Trust, a government-funded body, to combine their technologies to create the breakthrough needed for mass market scale. They are working with an unnamed Japanese carmaker……

Xeros

Technology Strategy Board awards prestigious grant to Xeros

Xeros has been awarded a £250,000 grant for research and development by the Technology Strategy Board to accelerate the development of a domestic laundry machine, which will fully exploit Xeros’ environmentally friendly technology. The grant, the highest that can be awarded through the Technology Strategy Board’s Smart scheme, will be match funded by shareholder funds following a successful private equity funding round in 2011.

Xeros has established a process that delivers superior cleaning performance yet uses significantly less water, energy and detergent than conventional washing systems. The process uses small nylon polymer beads to ‘attract’ stains. Within the Xeros washing system, the gentle flow of the beads acts just like water. They tumble with the washload and transport stains off garments to be locked into the nylon’s molecular structure.

Building on its proven success in the commercial laundry market, Xeros will use the grant to design a washing system of comparable size, appearance and cost to conventional front loading machines that are used in millions of homes across the country. When compared to these machines, independent analysis1estimates that a Xeros domestic system would slash energy use by half and reduce water consumption by up to 80 per cent. It would also cut CO2 emissions per wash by 25 per

cent.

Domestic washing machines consume approximately 50 litres of water per wash. On average, washer/dryer systems account for 13 per cent of household energy use. If all UK households were fitted with machines powered by Xeros technology, the potential savings to UK consumers would total more than £2 billion per annum. It would also represent a net reduction of 4.2 million tonnes of CO2 per annum, the equivalent of taking 1.4 million cars off UK roads.

The domestic Xeros washing machine will be approximately one fifth of the size of the commercial technology that continues to be used by Jeeves of Belgravia and Watford Launderers & Cleaners as part of a long term trial.

Bill Westwater, Chief Executive of Xeros, said: “We are delighted that the Technology Strategy Board has awarded a significant grant to Xeros. Together with our own shareholder funding it will enable Xeros to accelerate our plans for the domestic market place. This has long been part of our business plan. If the application of our technology in this market matches the proven viability of our large size machines in the commercial laundry, we are one step closer to our ultimate goal, namely to convert

the world of aqueous washing to Xeros bead cleaning.”

Stephen Browning, Head of the Smart programme at the Technology Strategy Board, said: “The Smart scheme is designed to support research and development by SMEs that has the potential to offer economic growth and lead to the introduction of successful new products and processes. We are therefore very pleased to support Xeros through this grant as it will enable them to make the investment in staff, technology and materials needed to accelerate the development of their innovative product.”